Horizontal centrifugal mining dredger slurry pump

Product Description

Horizontal centrifugal mining dredger Slurry Pump

Advantage:

high head

large capacity

high performance

Detailed description of AM slurry pump

1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump

2) High head, large capacity, high efficiency.

3) Good NPSH performance.

4) Widely application: They are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, explosive sludge in metal melting, dredging in dredger and course of river and other fields.

5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

6) Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy).

7) The frame plate for type AM pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber.

8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

9) Centrifugal seal, mechanical seal and packing seal are available.

10) The shaft seals for type AM pumps may be adoptable of gland seal or expeller seal

11) The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Pump Parts

1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity.

2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance.

3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life.

4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety.

5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

AM Slurry Pump Performance Parameters

Type | AM Slurry pump |

Flow (m3/h) | 3-6700 |

Head (m) | 5-68 |

Power (kw) | 15-1200 |

Eff. (%) | 85-96 |

Pass Particle Size (mm) | 19-135 |

Material | High Cr Alloy, Rubber |

Factory

Pump spare parts

Pump show

- Standard wooden cases package, if special requirements, should be inform in advance;

- Shipping by sea, by air, by train and truck all available;

- Delivery date: vary from 5-30days according to different model and quantity.

- 1 year guarantee of whole machine set, except the flow parts

- 24hours *7 days service is available

- Calling or door to door service

- User manual and maintenance instruction is available

Q1. Are you a manufacturer?

Yes, we have been in centrifugal pumps manufacturing and marketing industry over 32 years.

Q2. What markets do your pumps export to?

Europe, North & South America, SouthEast Asia, Africa, Oceanica, Middle East countries. Our overseas agent in Italy, Russia, Canada, France, America, Middle East, Asia and Africa are gradually improving.

Q3. What information should I let you know if I want to get a quotation?

Please let us know the pump capacity, head, medium, operation situation, quantity, etc. As much as your provide, the precision

and accurate model selection.

Q4. Is it available to print our own brand on the pump?

Totally acceptable as international rules.

Q5. How can I get the price of your pump?

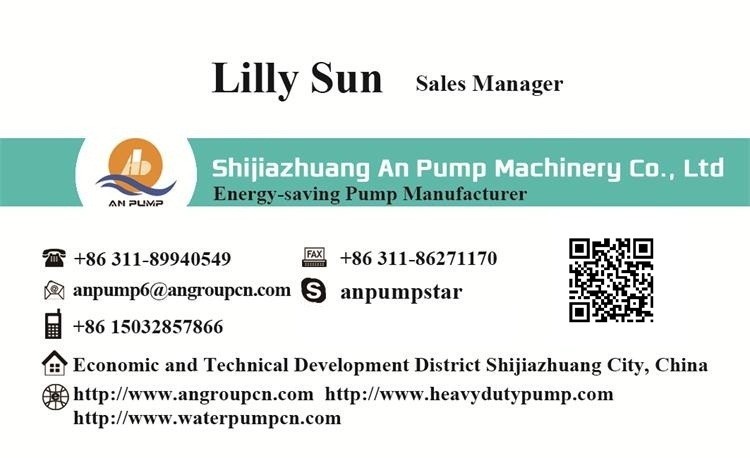

You can connect with us through any of the following contact information. Our personalized service person will respond you within 24 hours.

Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Minging Dredger Pump、Sand Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Slurry Pump > AM Centrifugal Slurry Pump

Premium Related Products