100 bar high pressure multistage pump

Product Description

100 bar high pressure Multistage Pump

1.Multistage Pump Introduction:

Multi-stage section centrifugal pump, the excellent hydraulic models are high-efficiency, energy-saving, and have wide performance range, operating safety & steady, low noise, long life and installing

& repairing is very convenient etc. It can deliver heat water, oil, corrosive or wear albe medium by changing the material,

seal or adding cooling system.

1. Multi stage pump can deliver the neuter mineral water which solid particles percent≤ 1.5%(solid Dia, < 0.5mm) and other similar sewage,

2. Temperature of the liquid is ≤ 80°C. It is suitable for steel works, mines, cities projects etc.

This kind pump can deliver the corrosive liquid without solid particle, which temperature is from -20°C-150°C

The multi stage pump deliver oil or oil products without solid grain, viscosity ≤ 120ct, range of temperature is from -20°C to 150°C

3.Compact and reasonable structure

4.Shaft seal can be mechanical seal or packing seal

5.Advanced hydraulic model to feature high efficiency and little energy consumption

Suitalbe for mine, city Water Supply and Sewerage Engineering

Transfer watery liquid medium, without solid particle, temperature under 80°C

Suitable for boiler water feed or deliver medium similar with hot water, without solid particle, temperature below 105°C

Suitable for stain steel, mine, sewage transferring process.

Transfer mine water with solid partical content under 1.5% or similar sewage, temperature under 80°C

Suitable for transferring Corrosive liquid without solid partical, temperature between -20°C~105°C

Suitable for transferring Oil and petroleum products without solid partical, temperature between -20°C~150°C, viscosity under 120cSt

Applications List

- Cooling system

- Commercial-Water

- Commercial-Treatment

- Commercial-Fire/Fighting

- Light Industry-Water

- Light Industry-Treatment

- Agriculture-Irrigation

- Golf/Turf-Irrigation

- Municipality-Water

- Municipality-HVAC

- Water supply or boosting

- Air-conditioning system

- Domestic and industrial cleaning

- Water treatment and water purification

Type | QD(G) |

Capacity (m3/h) | 120-1100 |

Head (m) | 967-2500 |

Speed (r/min) | 2980-5410 |

Eff.(%) | 68-86 |

NPSHr (m) | 4.5-23.5 |

Power (kw) | 710-8000 |

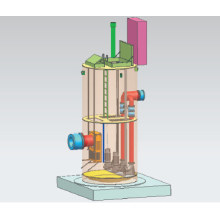

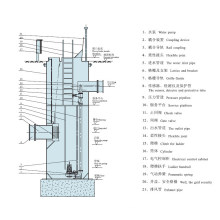

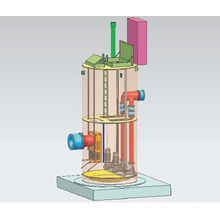

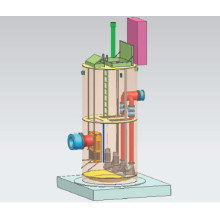

For this series horizontal multistage Centrifugal Pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it.

Stator portion

Consists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward.

Rotor portion

Consists of a shaft, impeller, balancing disk, muff etc. Parts.

Bearing portion

The whole rotor is supported by the roller bearings or

sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil.

Cooling and seal of pump

The joint-part between suction section, intermediate

section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump.

An Pump Machinery is your Best Pump Manufacturer

An Pump Machinery Co. ,Ltd is the pump manufacturer with 50+ years experienced

Our pumps export to over 90 countries all over the world in mining, power plant, dredging and dredge, hydraulic, irrigation, pulp transfer, chemical, construction, sea water and oil & gas transfer etc.

Factory Show

Factory Tour

Certificate, your reliable

Your 24x7 manufacturer team and service for:

An Pump Machinery Company to Customers:

1)Quality first. We guaranteed every part of the pump must be inspected closely

2)We can help you select suitable pump model according to your working condition and requirements.

3)We can design the related base or engine for your pumps.

4)Fast delivery time, large quantity of spare parts in stock.

24x7 service for your pump:

Product Categories : Water Pump > QDL Vertical Multistage Pump