China made horizontal centrifugal pump for hydrocyclone 200 kw

Product Description

China made horizontal Centrifugal Pump for hydrocyclone 200 kw

AM centrifugal slurry pumps are mainly used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc.

Detailed specification:

1. Horizontal, cantilevered, centrifugal, single stage Slurry Pump

2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

3. Wear resistant and anti-abrasion wet parts: high chrome alloy and rubber etc. They are completely interchangeable with each other

4. Easily replaceable liners: Liners are bolted to the casing.

5. Easy adjustment of impeller:

An impeller adjustment mechanism is provided below the bearing housing.

6 Discharge direction can be positioned at intervals of 45 degrees.

7. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

8. Sealing type: packing seal,expeller sealing and mechanical seal.

9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

Structure drawing

Slurry pumps performance parameters

Model | Flow | Head | Frame | Max Power | Max Particle Size | Material |

AMB 1.5x1 | 3 - 40 | 5 - 68 | B | 15 | 20 | High Cr Alloy/Rubber |

AMB 2x1.5 | 7 - 87 | 8 - 63 | B | 15 | 19 | High Cr Alloy/Rubber |

AMC 3x2 | 21 - 139 | 10 - 64 | C | 30 | 25 | High Cr Alloy/Rubber |

AMC 4x3 | 14 - 201 | 7 - 53 | C | 30 | 28 | High Cr Alloy/Rubber |

AMD 4x3 | 14 - 201 | 7 - 53 | D | 60 | 28 | High Cr Alloy/Rubber |

AMD 6x4 | 25 - 504 | 11 - 62 | D | 60 | 44 | High Cr Alloy/Rubber |

AME 6x4 | 25 - 504 | 11 - 62 | E | 120 | 44 | High Cr Alloy/Rubber |

AME 8x6 | 43 - 900 | 8 - 63 | F | 120 | 63 | High Cr Alloy/Rubber |

AMST 10x8 | 220 - 1800 | 9 -65 | ST | 560 | 76 | High Cr Alloy/Rubber |

AMST 12x 10 | 35 - 2088 | 7 - 67 | ST | 560 | 86 | High Cr Alloy/Rubber |

AMST 14x12 | 40 - 3564 | 11 - 65 | ST | 560 | 90 | High Cr Alloy/Rubber |

AMTU 16x14 | 324 -4700 | 10 - 65 | TU | 1200 | 123 | High Cr Alloy/Rubber |

AMTU 20x18 | 570 - 6700 | 11 - 59 | TU | 1200 | 135 | High Cr Alloy/Rubber |

Pump Parts

1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity.

2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance.

3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life.

4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety.

5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

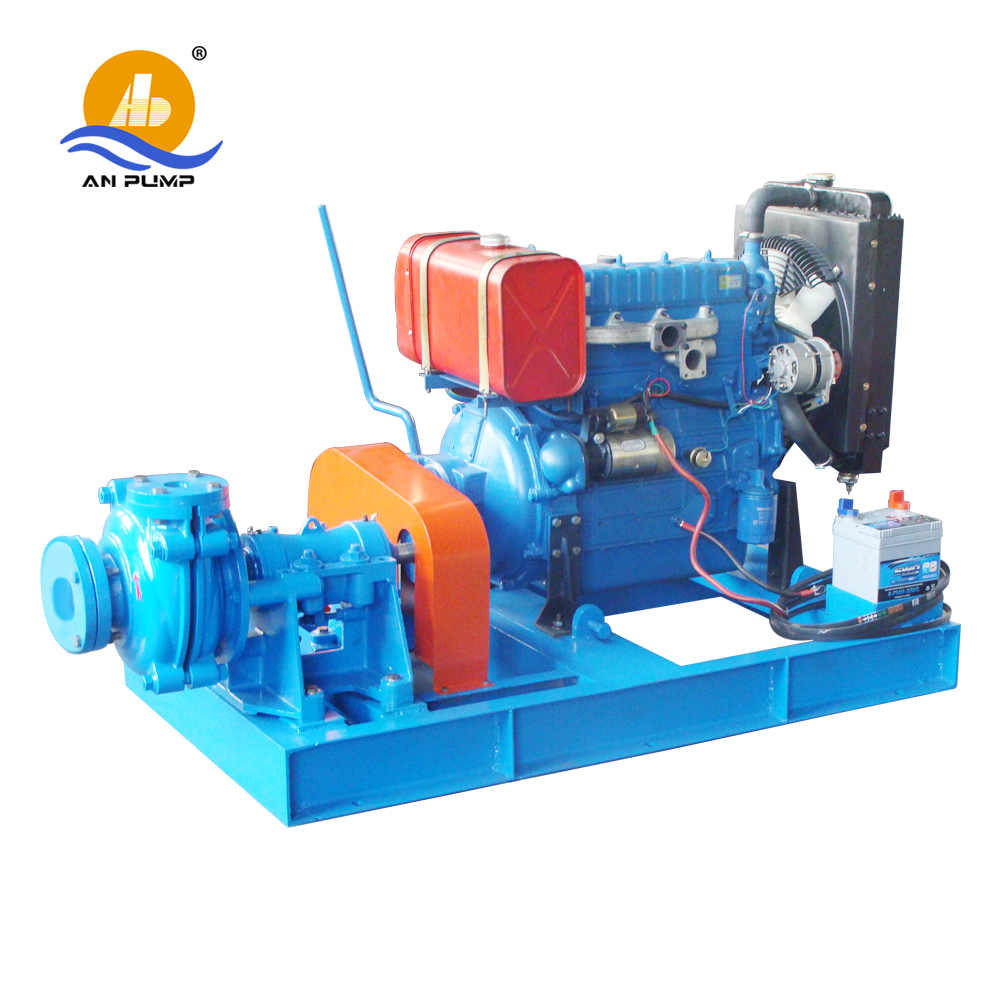

Pump Drive Type

Factory

Contact Us

Product Categories : Slurry Pump > AMR Rubber Lined Pump